Context

Since around ten years, Dumoulin innovates in the development of new ranges of products, in particular extruded feed intended for food applications and for very specific target markets, in Belgium and in the export. At the end of 2012, a new range of products based on thermo-treated soya seeds after flaking and toasting was also developed. The production of these new flaked and extruded products requires the development of analytical tools suited to follow the transformation process and, at the same time, control the quality of the finished product. It is in this context that the Dumoulin Company participated in partnership with the CRA-W since September 2013, and for a 2 years period, to a project “First Enterprise” (Project 7047) financed by the Walloon Region. CRA-W contributed with its expertise in the development of analytical solutions based on Near Infrared Spectroscopy (NIRS).

Objectives

The main objectives of this project were:

1° sharing of scientific CRA-W know-how on near infrared spectroscopy and training of an engineer at the factory in Andenne,

2° quality assessment of the raw material by NIRS to monitor the diverse supply (lab analysis),

3° quality assessment of specific products with high added value (flaked and extruded products) by NIRS (on-line and lab analysis).

To have a better control of the quality for those specific products will permit DUMOULIN to differentiate itself from its competitors in the Belgian and foreign markets, which is a logical result of the diversification of its offer and essential to support the innovation within the company and to maintain its growth.

Expected results

At the end of the project, the trained engineer will have acquired the necessary scientific knowledge and technical competence in the field of quality analysis using NIRS. Moreover, he will be able to develop current and new applications of this technology for the quality control of flaked and extruded products at Dumoulin. After getting experience in the production of feed at the Andenne factory, in particularly flaked and extruded products, he will study the basics of the Near Infrared spectroscopy and the applications already realized within the CRA-W. After the acquisition of these expertises, he will participate, in collaboration with the CRA-W, at the evaluation of various types of instruments (in laboratory and on-line) and the elaboration of calibration equations for raw materials and new flaked and extruded products according to important nutritional quality criteria (protein, fat, fiber and starch contents) as well as storage parameters (humidity).

Results obtained

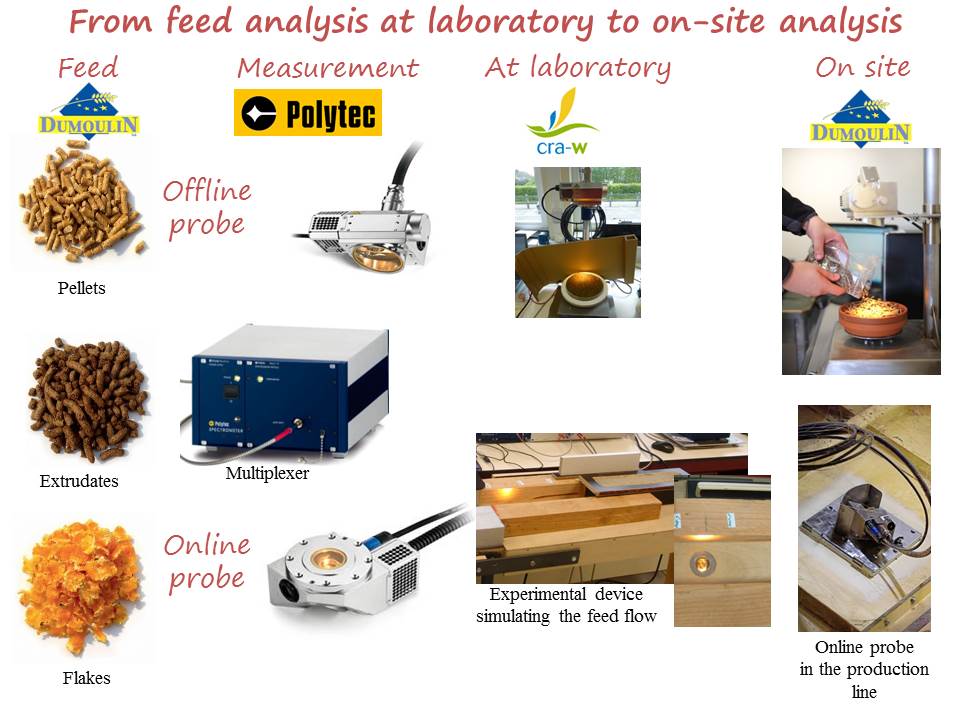

To assess, at laboratory level and online, the quality of feed produced by the company Dumoulin, a Polytec NIR spectrometer covering a range of wavelength from 850 to 1650 nm was selected. This instrument is combined to a multiplexer that toggles the analysis using either offline probes for laboratory or online probes for production line. The main choice criteria were the ability to perform online analyses in a very fast rate (1500 scan / sec) and the device's robustness (equipped with technology "Diode array" reducing the number of moving parts).

In a first step , the instrument was installed at the CRA-W facilities combined with an experimental device simulating the feed flow. Reference values were obtained by measuring, in duplicate on the FOSS XDS spectrometer, samples of different types of compound feeds (pellets or extrudates) and by applying the CRA-W’s calibration equations. This has permitted to save significant time and money. Some samples were further analysed by an accredited laboratory with reference methods to control the predicted values. All these samples were also analysed on the Polytec spectrometer using the available two probes. Calibration equations were developed for four types of feed (beef, pig, nitrogen supplement, extrudates) and 6 parameters: moisture, crude protein, fat, crude fiber, starch and ash. Most offline equations showed a good performance with cross-validation R2 higher than 0.9 and RPD higher than 3.

After the calibration and validation step performed in the CRA-W laboratory, the spectrometer with the two probes was moved to Dumoulin. The online analysis probe was installed in the hopper after the mixer of raw materials, to analyse all the products manufactured in the company. A phase of programming and automation was needed to store the prediction results in the database and use them for online control. An update of the equations was also necessary to take into account the shape of the product (flour before extrusion or compression). The majority of online equations had a higher cross-validation R2 and a RPD allowing discrimination between high and low values of the 6 studied parameters. For measurements with the offline probe, the lab equations developed at CRA-W in the 1st step were used.

The NIR spectrometer installed at the Seilles site (Belgium) can analyse online all product lines (as flour state) and provide the customer with the predicted values of each batch. The probe installed at the analytical laboratory allows simultaneously controlling the quality of raw materials at the reception and the quality of the finished products (in the form of pellets or extrudates). Improving the quality of finished products is beneficial to the renown of the company and the reduction of shipments of non-compliant products can reduce costs related to litigation with customers.

Contribution

The CRA-W shares its expertise in Near Infrared spectroscopy. Moreover, he plays a determining role in the development of calibration equations for quality control of the feed production at the DUMOULIN Company.

Partners

The “First Enterprise” project is coordinated by the company DUMOULIN in partnership with the CRA-W.

CRAW off coordinator

BIEMAR Denis, REUTER Werner (DUMOULIN)Funding

- SPW-DG06