What is thermally modified wood?

Wood thermal modification is a process that aims to induce irreversible chemical changes in order to provide wood certain properties. This is achieved by exposing the material to high temperatures (approximately 200°C) in the absence of oxygen. This is also known as torrefaction.

By degrading a portion of the hemicelluloses, which represent 20–30% of the mass of the material, the wood absorbs less water and becomes less susceptible to fungal attacks. It is said that the wood becomes more durable. The reduction in the hydrophilicity of the wood also improves its dimensional stability: the wood becomes less prone to swelling and shrinking. In this way, thermal modification makes it possible to use the wood outdoors when the species is not naturally suited to this usage. This is particularly interesting for several hardwood species found in Wallonia, which are weakely durable or not durable at all, despite boasting advantageous mechanical properties.

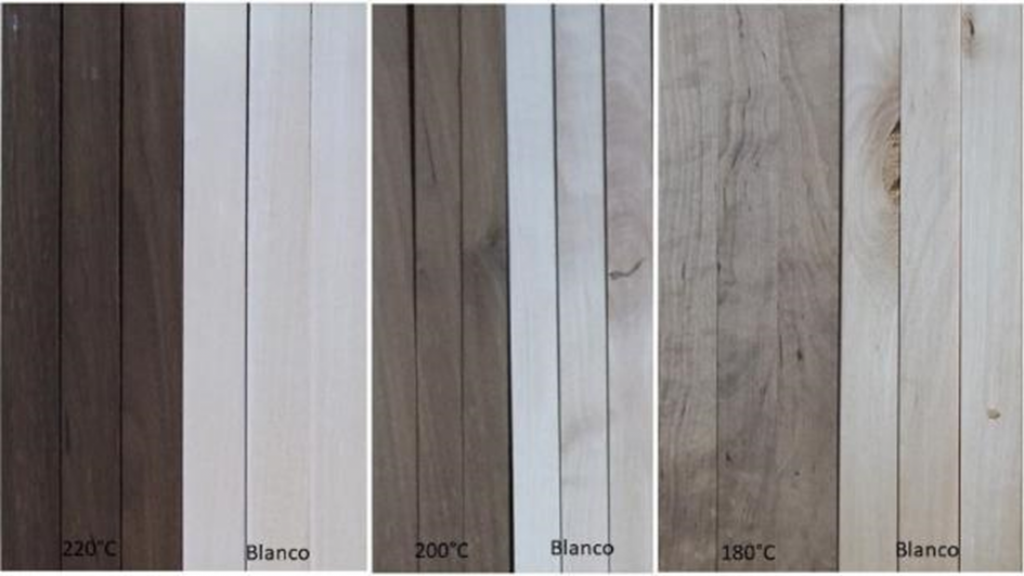

Everything has a downside though: wood thermal modification lowers some of its properties, including stiffness and strength. The modifications made to the original properties can vary considerably, depending on the temperatures the wood is exposed to, as well as on the duration of the exposure. Therefore, the challenge for manufacturers is developing a product whose properties are clearly controlled, making it possible to ensure the material is fit for its intended uses.

What research is the CRA-W conducting?

The DURPOP project, which is being carried out in conjunction with the LTB and the Belgian company DURWOOD, aims to develop thermal-modification procedures of poplar boards for use as cladding. Achieving this goal will provide an alternative to using biocidal products to preserve the wood (the poor natural durability of poplar wood is not conducive to being exposed to weather conditions) and to importing exotic species (e.g. Western Red Cedar or Ayous). The absence of biocidal products in wood also makes it easier the recycling of the material at the end of its life cycle.

Furthermore, current industrial procedures are long (approximately 36 hours per cycle) and energy intensive. To this end, the RADIOWOOD project has been designed to improve the energy efficiency of the thermal-modification process. Wood can be heated using electromagnetic waves (microwaves or radio frequencies), just like food in a microwave. This process is referred to as dielectric heating. This instantly acts in the core of the material and causes the wood to heat up throughout its volume. This makes it possible to avoid the thermo-insulating properties of the wood, and to reduce the time required to achieve a given temperature, making it ten, or even one hundred times faster. The RADIOWOOD project, which has been conducted in conjunction with the LTB, ULiège (Institut Montefiore) and the company Technic One, aims to integrate dielectric heating into an industrial process of wood thermal modification. The results obtained via this research could also be used for the drying and sanitary treatment of wood, as these processes require lower temperatures.

Funding: The Walloon Recovery Plan, under the coordination of Filière Bois Wallonie

Photo : Boards that have been thermally modified at different temperatures compared to unmodified boards (Blanco).